BuzzFeed Community is a hub for BuzzFeeders to create awesome quizzes and posts that people love. Make your own, or browse what other people are making.

Make your own post!

The Advantages Of Forming Large Elbow Push System

(1) need not tube for raw materials, can save Short di pipes making equipment and mold cost, and can be arbitrarily large diameter and wall thickness relatively thin Elbow push system. This push bend material is special, need not join the tube material, easy to control during processing. (2) billet pushing elbow is flat or curved surface, so the material is simple, easy to ensure accuracy, convenient assembling and welding, easy to control in the processing of raw materials, simple operation, no complicated process, and welding and assembling more convenient. (3) because it does not need any special equipment, especially suitable for field processing of large Elbow push system.

Wafer Type Dual Plate Check Valve

We manufacture top quality Wafer Type Dual Plate Check Valve made from cast iron, cast steel and stainless steel. Wafer Type Dual Plate Check Valves offered by us can be availed in various types like dual plate; single disc type and non slam check valves to meet the different requirements of the customers. We are identified as one of the celebrated Wafer Check Valves Suppliers in China. Wafer body style fits between FF or Flanged Tee Upper and lower PTFE thrust washers Dual plate Valves give maximum strength with minimum opening time Torsion springs assist Valve closure, preventing flow reversal

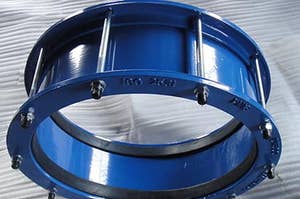

Flexible Coupling

It is suitable for steel, GRP, PVC, PE, Ductile Iron, Cast Iron and Asbestors Cement. When connecting PE pipes, It is important that Pipes and fittings inserts are fitted to the PE pipes. 1) All the flanged adaptors are assembled by " T " bolts. 2) Bolts, Nuts and Washers are in carbon steel Grade 4.8, 8.8 with zinc plated, Dacromet coating or according to customer's request. 3) Body material is Ductile iron GGG500-7. 4) Fusion bonded epoxy powder coating in blue, black or red or according to customer's Request. 5) Gaskets material: E. P. D. M., NBR or SBR. 6) Accommodate BS, DIN, ANSI flange drillings. Specification Unit Weight Sealing Ranges(mm) inches mm kgs 2" 50 3.6 59~732 1/2" 65 4.50 72~853" 80 4.83 88~1034" 100 5.51 108~1285" 125 7.74 132~1546" 150 8.32 159~1827" 175 11.30 192~2098" 200 9.95 218~23510" 250 14.50 271~28912" 300 18.62 322~34014" 350 26.00 374~39116" 400 28.85 417~43718" 450 33.40 480~50020" 500 50.00 526~54624" 600 54.10 630~650 7)Size: DN50mm-DN1600mm

Ductile Iron Fittings/Overview

We imported production technology of vacuous lost foam casting from Japan with high-tech production lines and modern inspection equipments. We also have sand casting type to produce fittings. Products for overseas markets covered all over the world. Fittings size from DN80 to DN2400 with full jointing types such as Standard Joint, Tyton (push on ) Joint, Mechanical Joint, Restrained Joint, Express Joint, Flange Joint etc AWWA C110 & C153 standard, ISO2531 standard, EN545 & EN598 standard is strictly carried out in production,the output is about 15,000 tons at present。Mainly used for municipal administration project, water supply, fuel gas, fire engineering main pipe line or the heavy caliber branch pipe line. Main products are Socket Tees, Flange tees, Double socket with branch flange tees, flange spigot, flange reducer,di puddle flange pipe, duck foot bend and flange twenty kinds of fittings and accessories. It also can make product as per the customers’ requirement because of lost form flexibility. Inside cements lining conform to ISO4179, Portland cement, synthetic resin paint, blast furnace slag and polyurethane lining according to customer requirement. Outside Zinc spraying and bitumen coating conform to ISO8179. Along with the higher requirement of corrosion prevention of customer, we also provide the Fusion-bonded-Epoxy coating for fittings, the coating powder has approved by WRAS international. The thickness and adhesion test conform to ISO4624.