1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

3D printing is more than just an innovative idea — it's already changing the way the manufacturing industry operates. Follow the history of 3D printing from its inception to its future in helping to shape our world. And check out #3DPrintMyGift to see the most creative gift ideas this holiday season.

3D printing is used for prototyping and manufacturing in many fields including architecture, engineering, automotive, and aerospace.

Instead of "subtractive manufacturing" (aka cutting away at material), 3D printing is "additive," as it prints out only necessary materials for the finished product. Therefore, it requires fewer raw materials to create an object.

In 1984, Charles Hull invented stereolithography, a printing process that allowed a 3D object to be created from digital data.

Engineers and designers have been using 3D printing for over 10 years, but mostly to mock up prototypes of their ideas.

Scientists have been experimenting with 3D printing organs since the late ‘90s.

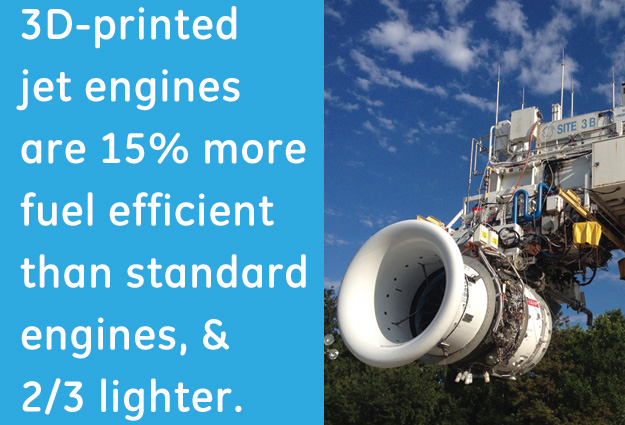

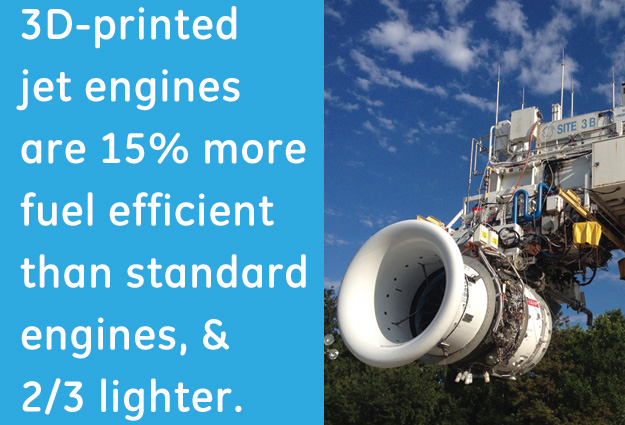

Because the engine is made from ceramic matrix composites instead of metal, it can operate at temperatures as high as 2,400 degrees Fahrenheit, where most alloys grow soft.

The market will only increase as 3D printing becomes more popular.

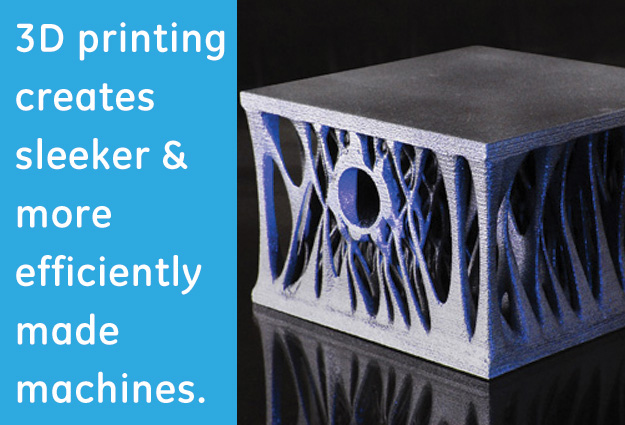

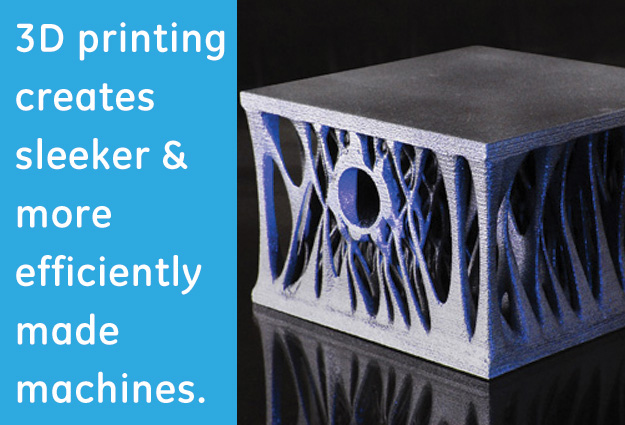

Because you only use materials that you need, you can optimize the design of machine parts.

The image above is GE's lattice cube. The organic design makes it about 1/3 of the weight of a solid cube while maintaining the solid's compression strength. The part is lighter and still as sturdy as a traditional part.

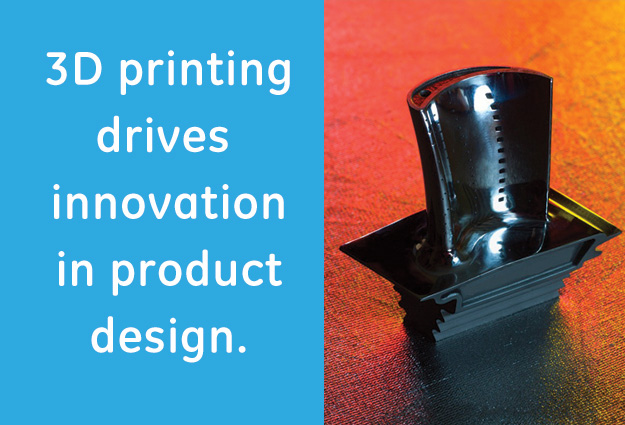

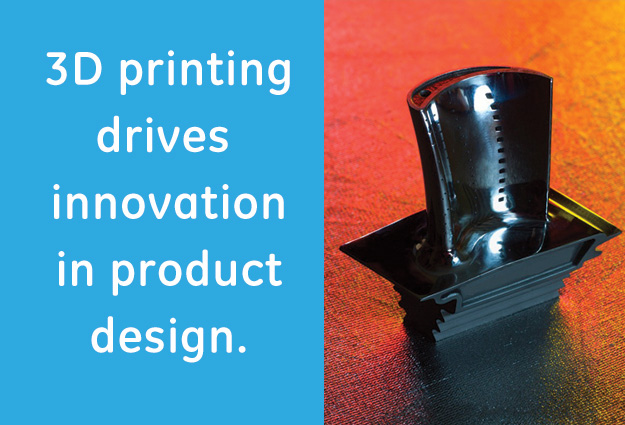

Pictured above is the internal geometries of a fuel nozzle. A part this complex would normally require the welding together of over 20 different components, but an additive manufacturing machine can build it as one piece.

This example of a high-pressure turbine blade was made from a cobalt-chrome alloy. The blade contains intricate cooling channels that would be otherwise difficult to manufacture. It is a good example of the new freedoms enjoyed by designers using additive manufacturing to make metal parts.

The printer’s build area is almost a cubic foot, large enough to print gas turbine parts.

David Joyce, president and CEO of GE Aviation, says that the technology liberated his business from the limitations of machining. What could not be done before is possible due to 3D printing.